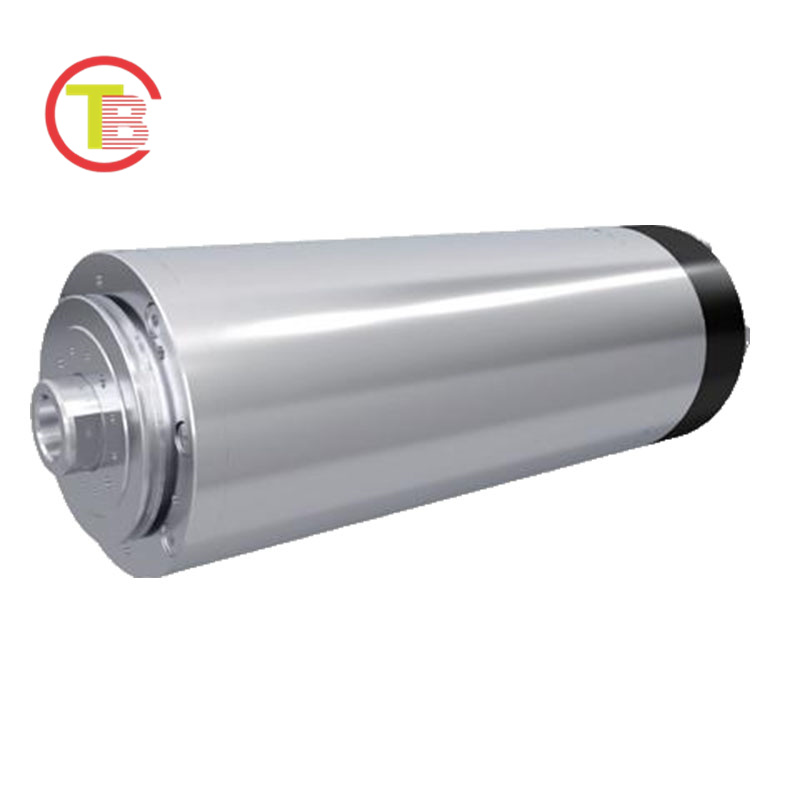

1.High Precision: For the PCB industry, the electric spindle has a static runout accuracy of ≤0.002mm and a dynamic accuracy of ≤0.006mm (factory standard). It has unparalleled high-precision characteristics, enabling higher-precision drilling capabilities.

2.High Power and High Torque Output: Combined with the performance features of the driver, it adopts a built-in motor design with a built-in three-phase variable-frequency asynchronous high-efficiency motor. This significantly improves output power, torque, and processing capability.

3.High Configuration: All electric spindles for this industry are equipped with an automatic tool change function and are also fitted with a motor temperature sensor.

4.High Energy Efficiency: On the premise of ensuring performance, air consumption is optimized to the minimum, reducing the operating cost for end customers.

5.Strong Compatibility and Good Expandability: The electric spindle for the PCB industry has excellent compatibility and can be widely used in various drilling machines in the circuit board industry. It can also be customized according to customer needs.

6.Low Failure Rate: The innovative and stable design makes the spindle’s stability significantly superior to that of products from industry peers.

7.Low Maintenance Rate: It adopts an inverted tool puller structure design. The tool puller mechanism consists of a shaft boss made of polymer material, a highly stable disc spring, and a collet made of high-nitrogen stainless steel, ensuring the spindle’s tool striking life is as high as 500,000 times.